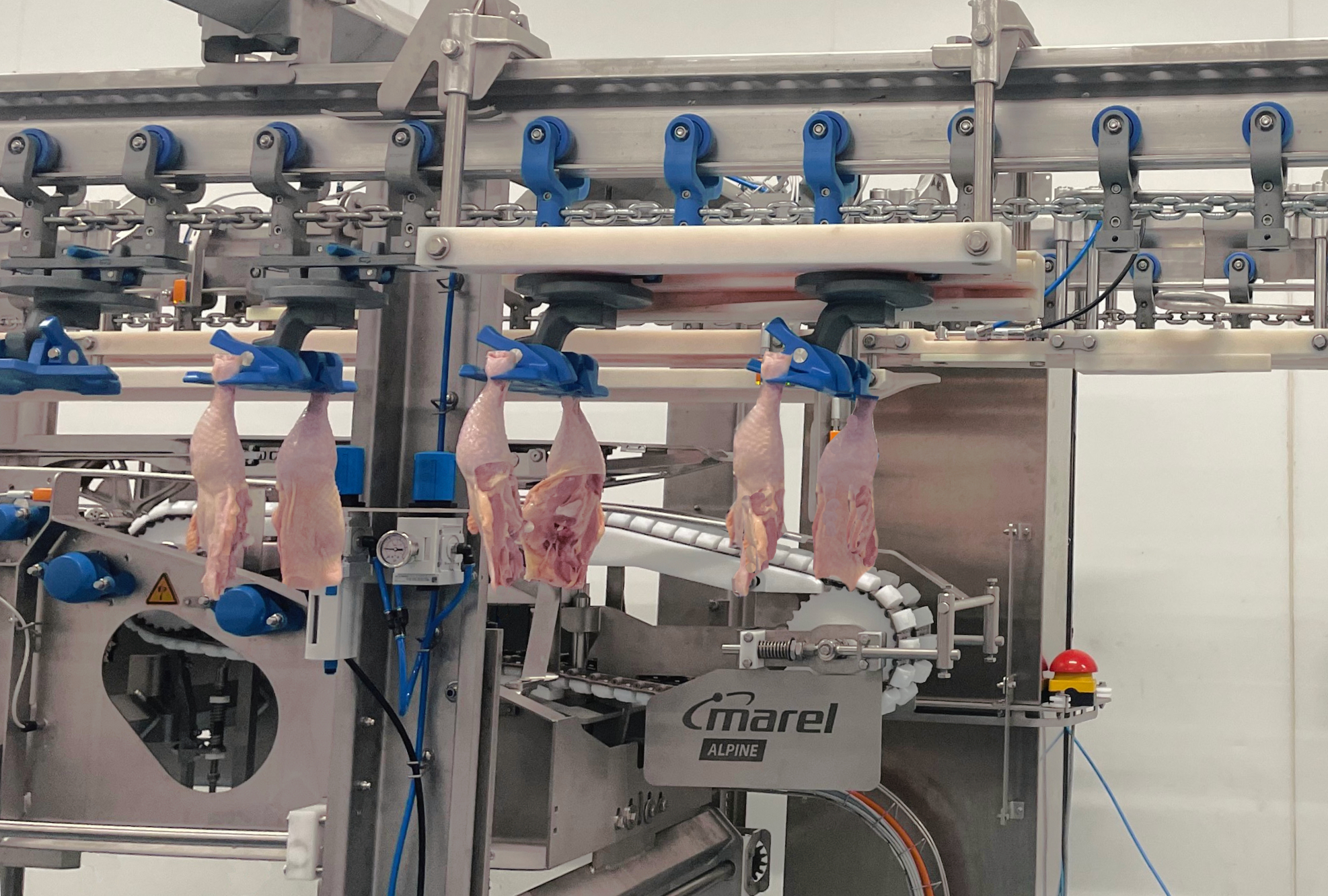

As demand for deboned leg meat continues to rise, ALPINE (Anatomic Leg Processor Revolutionary New Evolution) addresses processors’ needs for elevated manufacturing volumes whereas maximizing yield and top quality. The revolutionary ALPINE module, turning into in Marel’s ACM-NT cut-up line, represents a significant leap forward in anatomic leg processing. Its potential to maintain up top-level effectivity whereas coping with quite a lot of weights and reducing labor dependency models a model new commerce commonplace.

Pretty some superior utilized sciences have been carried out to understand ALPINE’s extreme effectivity, such as a result of the Hip Dislocation Wheel. This distinctive operate permits for actual administration of the hip tilting movement—wished to achieve an anatomical cut back—with out exerting excessive drive or eradicating the leg from the shackle. It results in improved effectivity and nearly nonexistent leg loss. To further enhance accuracy and reduce errors, ALPINE incorporates superior once more piece separation and detection know-how, which prevents incorrectly cut back legs. Optionally, processors can mix a selected module to remove groin pores and pores and skin robotically, meeting explicit market requires whereas saving considerable handbook trimming labor.

Ease of Operation

Equipped with a user-friendly HMI touchscreen, ALPINE makes it easy to enter a recipe that matches the actual traits of the incoming flock. This robotically engages the suitable machine settings to produce the perfect attainable leg yield. The show display screen moreover displays effectivity data, enabling processors to watch key metrics equal to once more piece detection, leg loss, and unprocessed legs. Constructed-in machine software program program presents this real-time and historic effectivity data. Such proactive insights lower the need for handbook intervention and cease downtime. ALPINE’s data-driven technique permits processors to maintain up peak effectivity with minimal need for repairs.

In depth Weight Differ with Fixed Outcomes

ALPINE is designed to course of high-yield anatomic legs all through an unprecedented range of fowl weights with out requiring foremost adjustments. This versatility is very priceless for processors coping with numerous flock weights, enabling them to optimize operations even in markets that course of big birds. Regardless of weight fluctuations, the tip outcome will on a regular basis be fixed: a high-yield leg. Appropriate with every water-chilled and air-chilled strains, ALPINE merely integrates into current setups and pairs excellently with Marel’s Thigh Fillet System, at a functionality of as a lot as 7,200 merchandise per hour.

Saving Labor

By retaining legs inside the shackles all via the tactic, ALPINE just about eliminates product drops and minimizes rework, downtime, and labor. Digital operation, automated settings, lowered need for adjustments, and actual effectivity monitoring further highlight its labor-saving advantages. Touchscreen administration and the broad weight range further contribute to ALPINE’s effectivity, ease of use, and continually extreme yield.

For further data, go to marel.com/alpine.